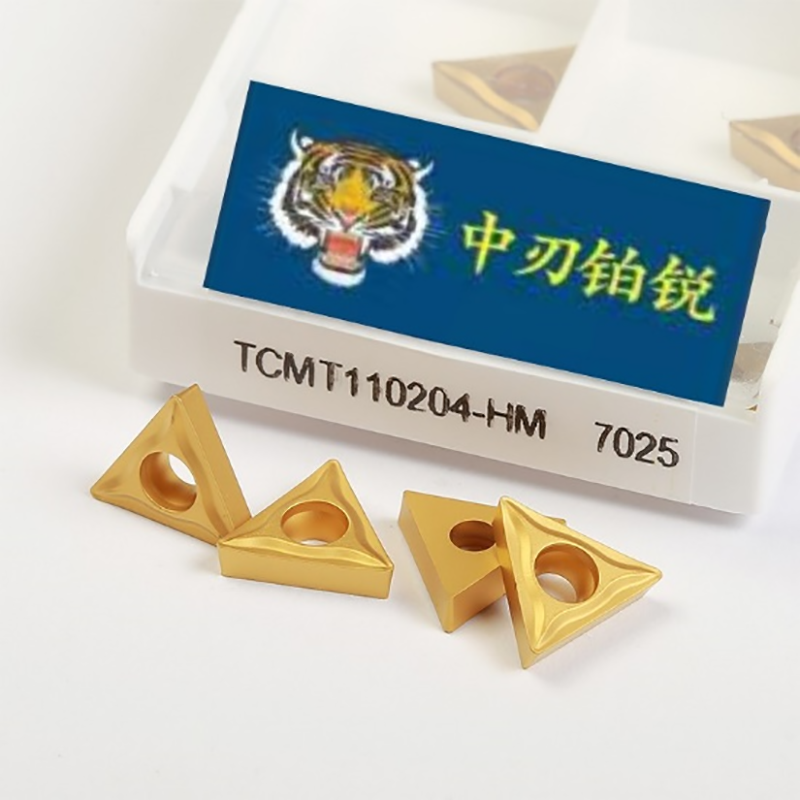

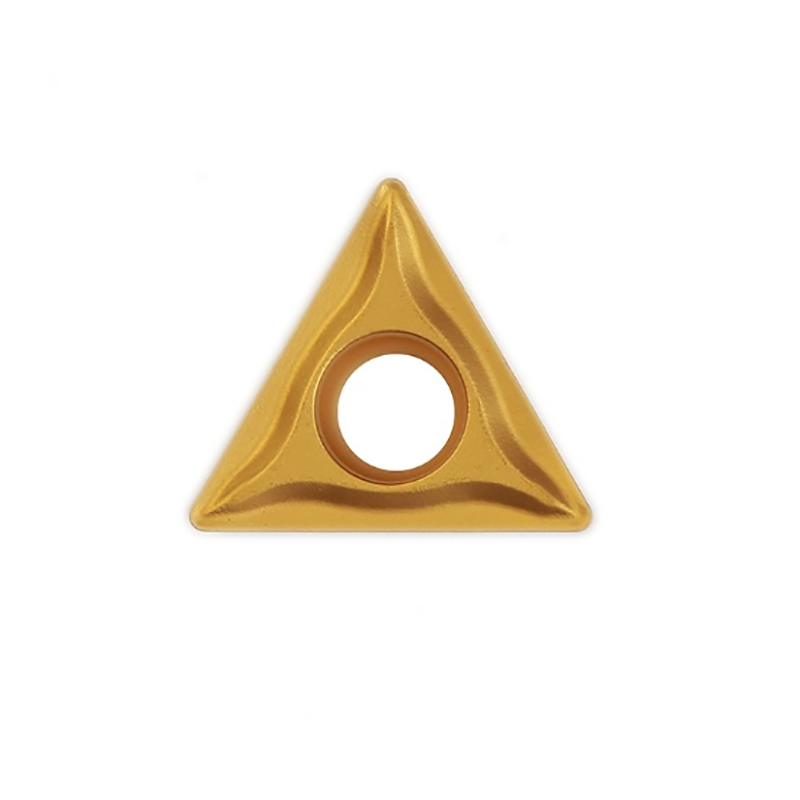

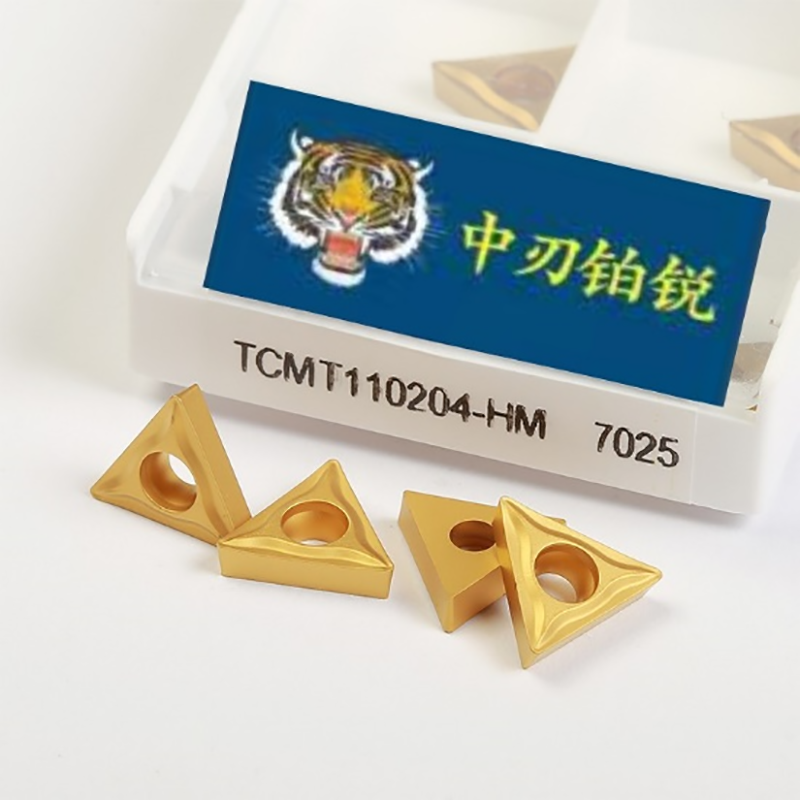

TCMT110204-HM Carbide Inserts Cutting Tools for Turning Machine Tools

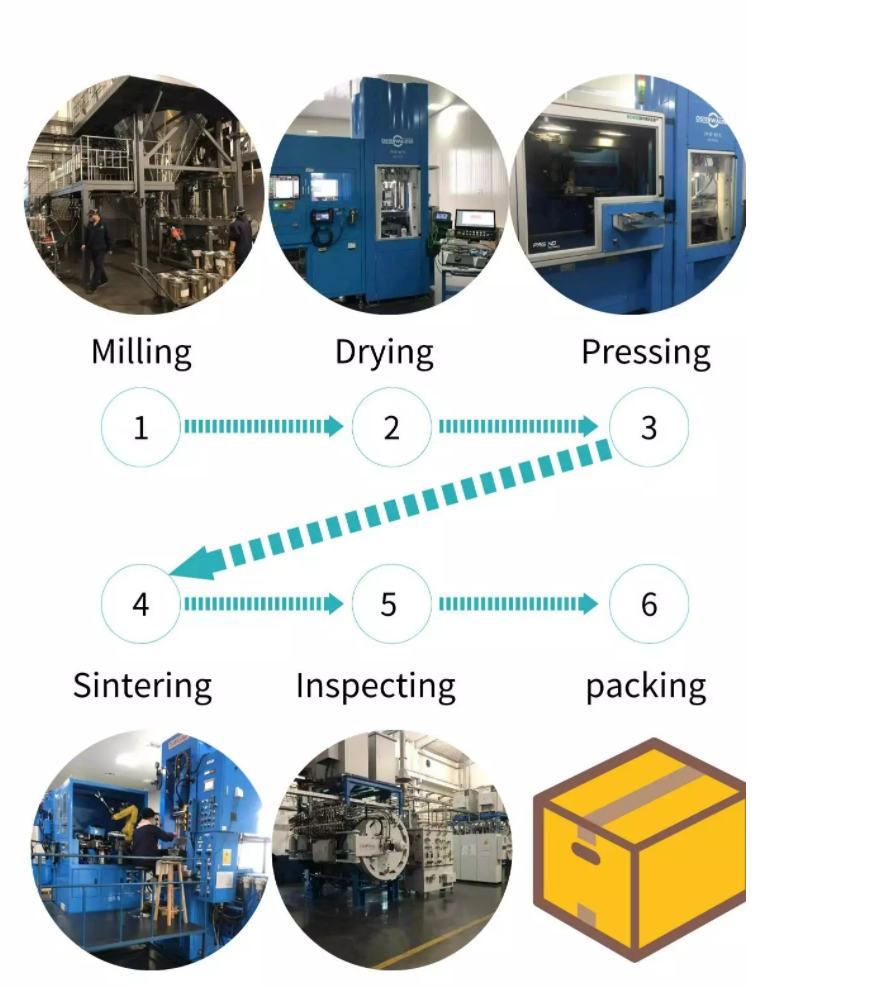

Production process

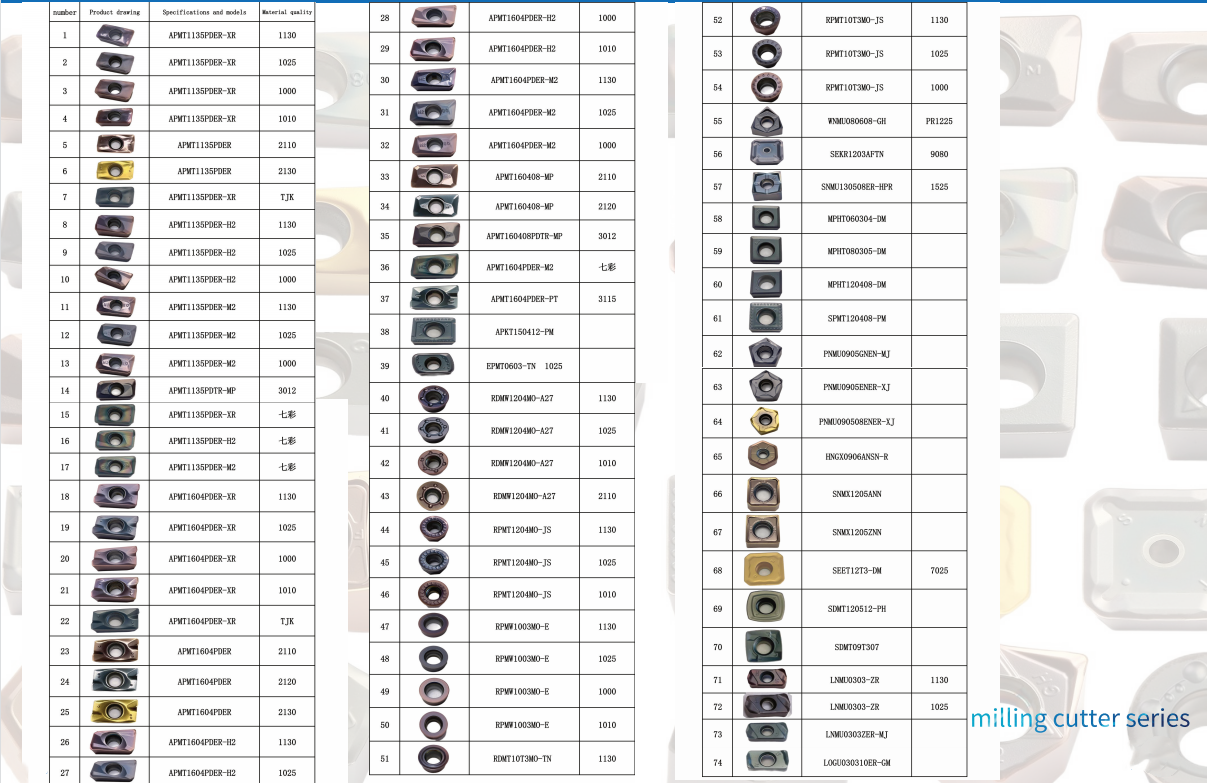

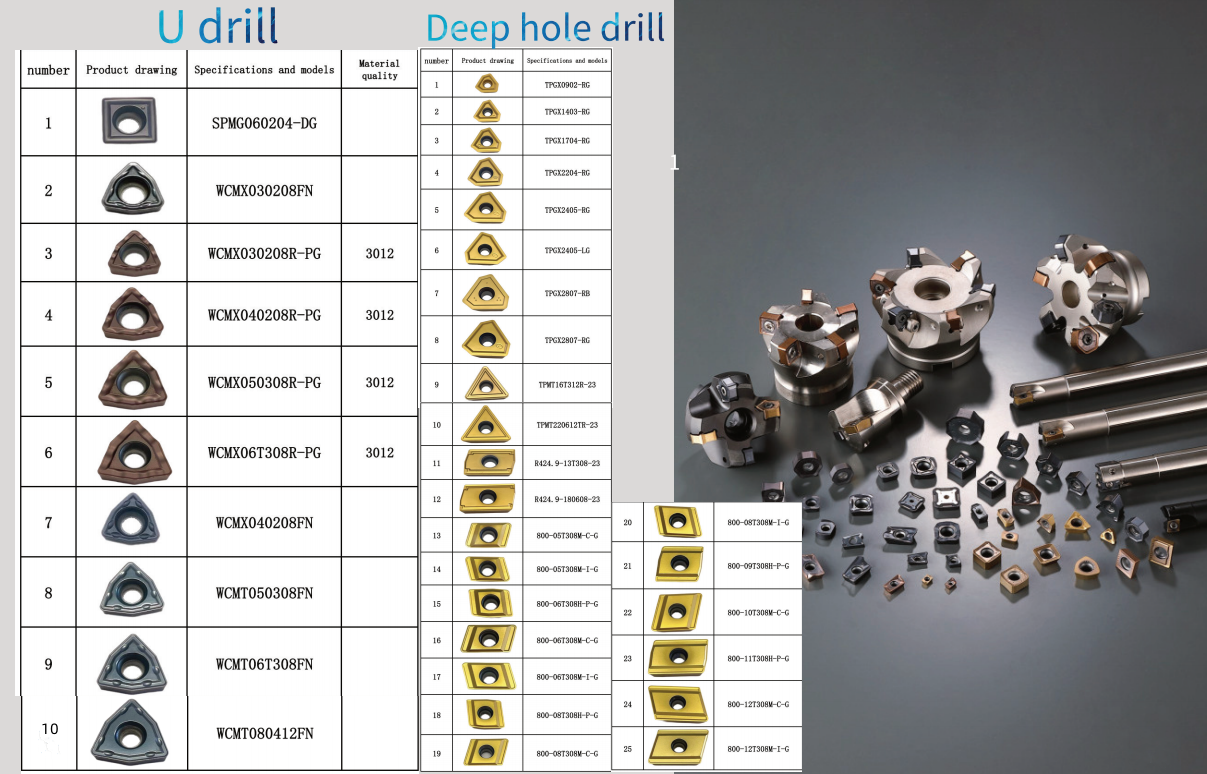

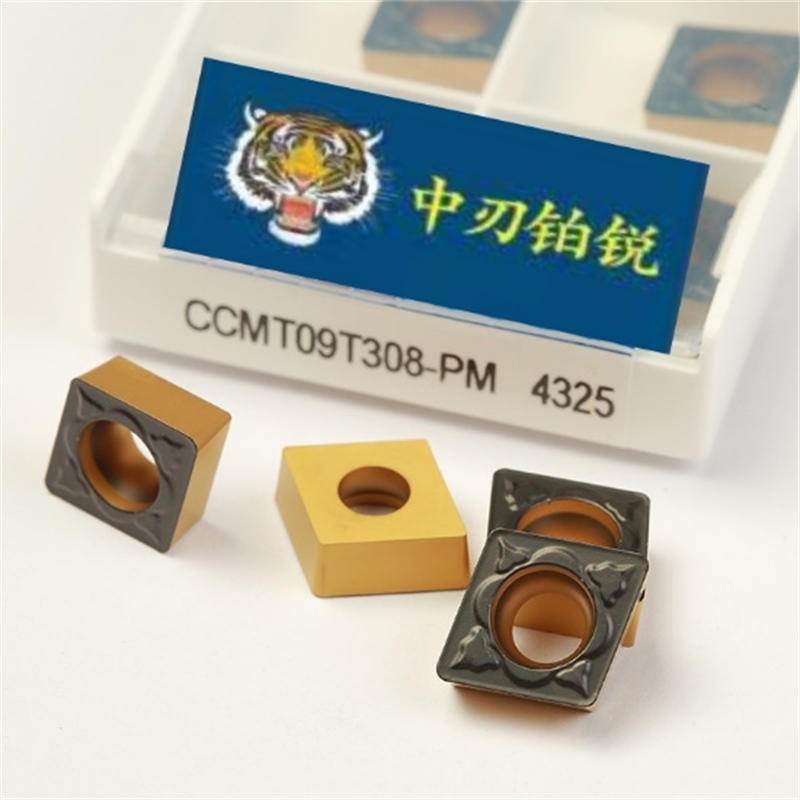

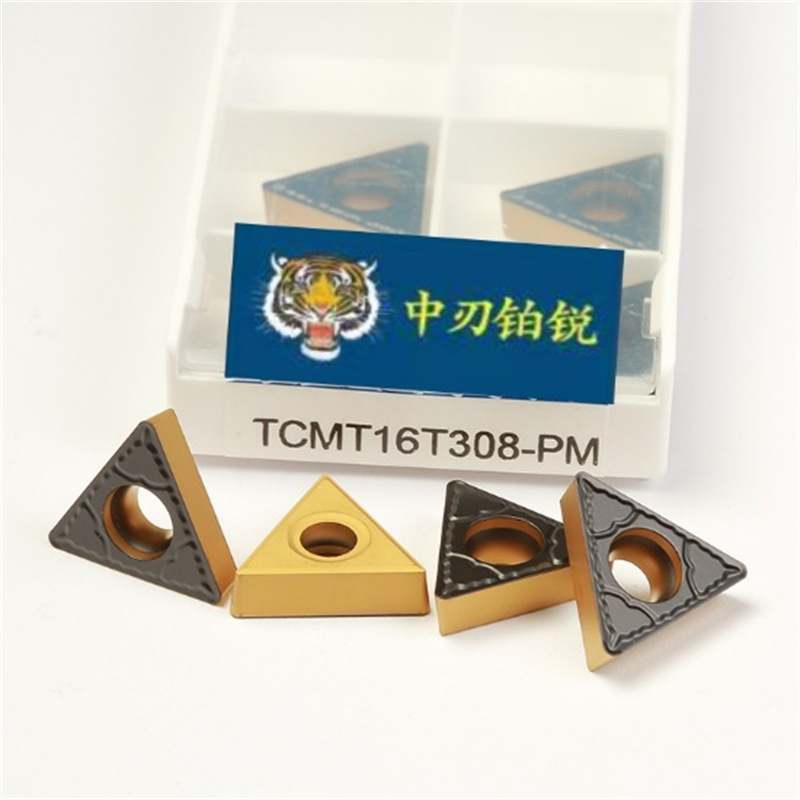

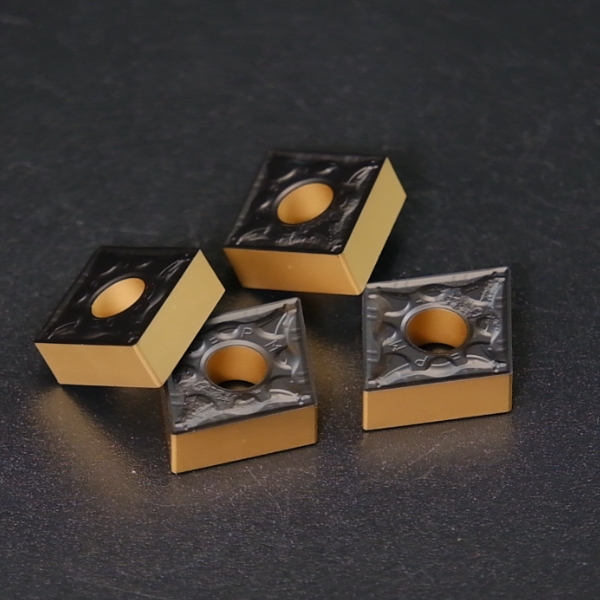

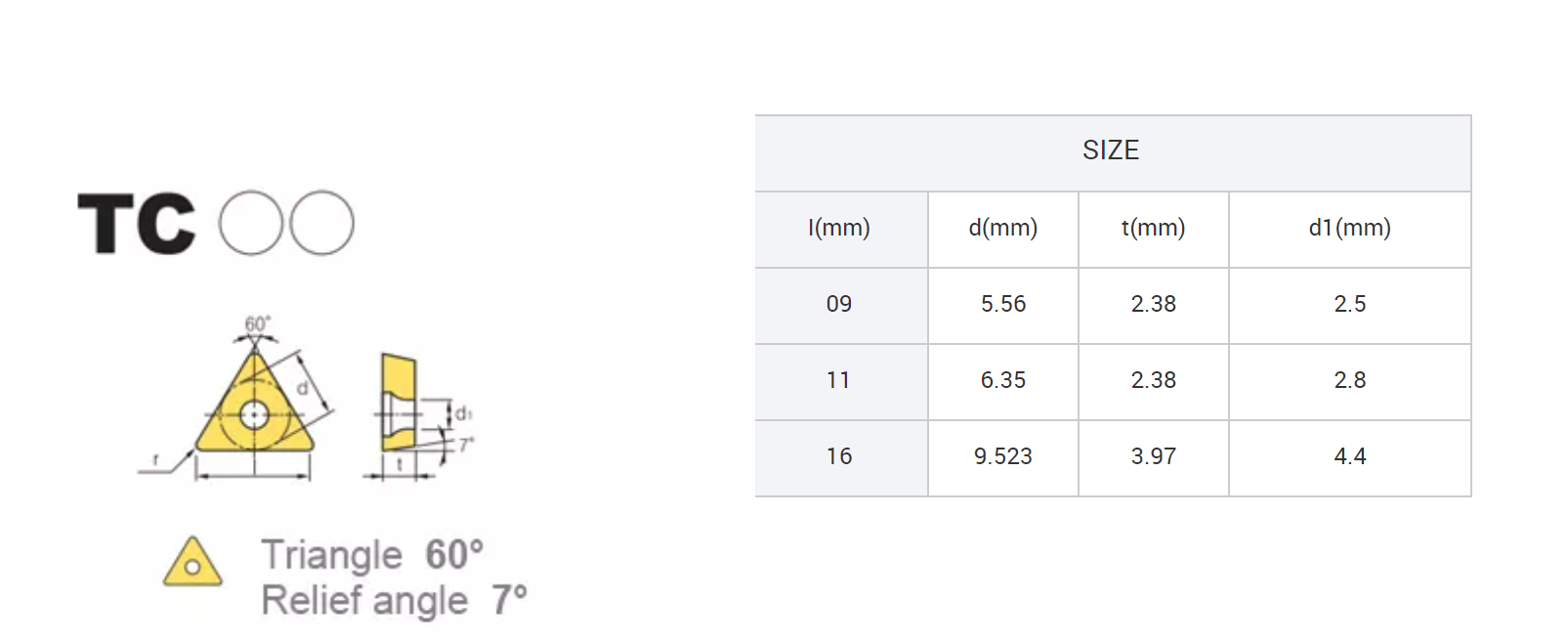

Product Specifications

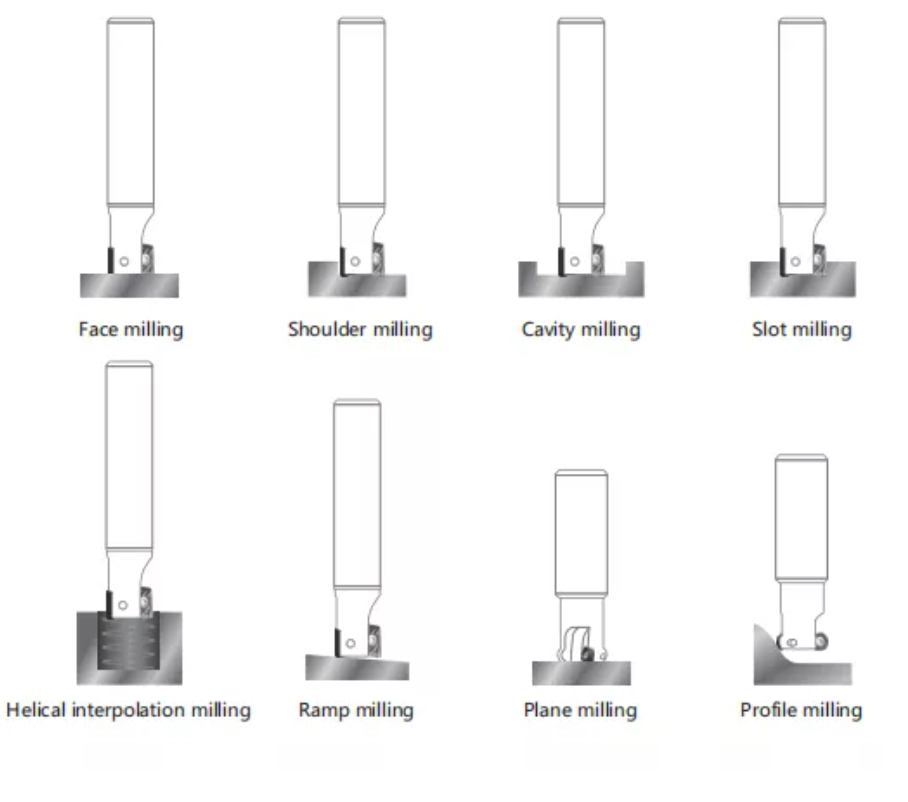

Whether you need a general milling or heavy milling inserts for face milling, shoulder milling, slot milling, profile milling, or ramp milling, or even milling higher requirements of surface smoothness, Our engineer can turn your design into a milling insert in just days.

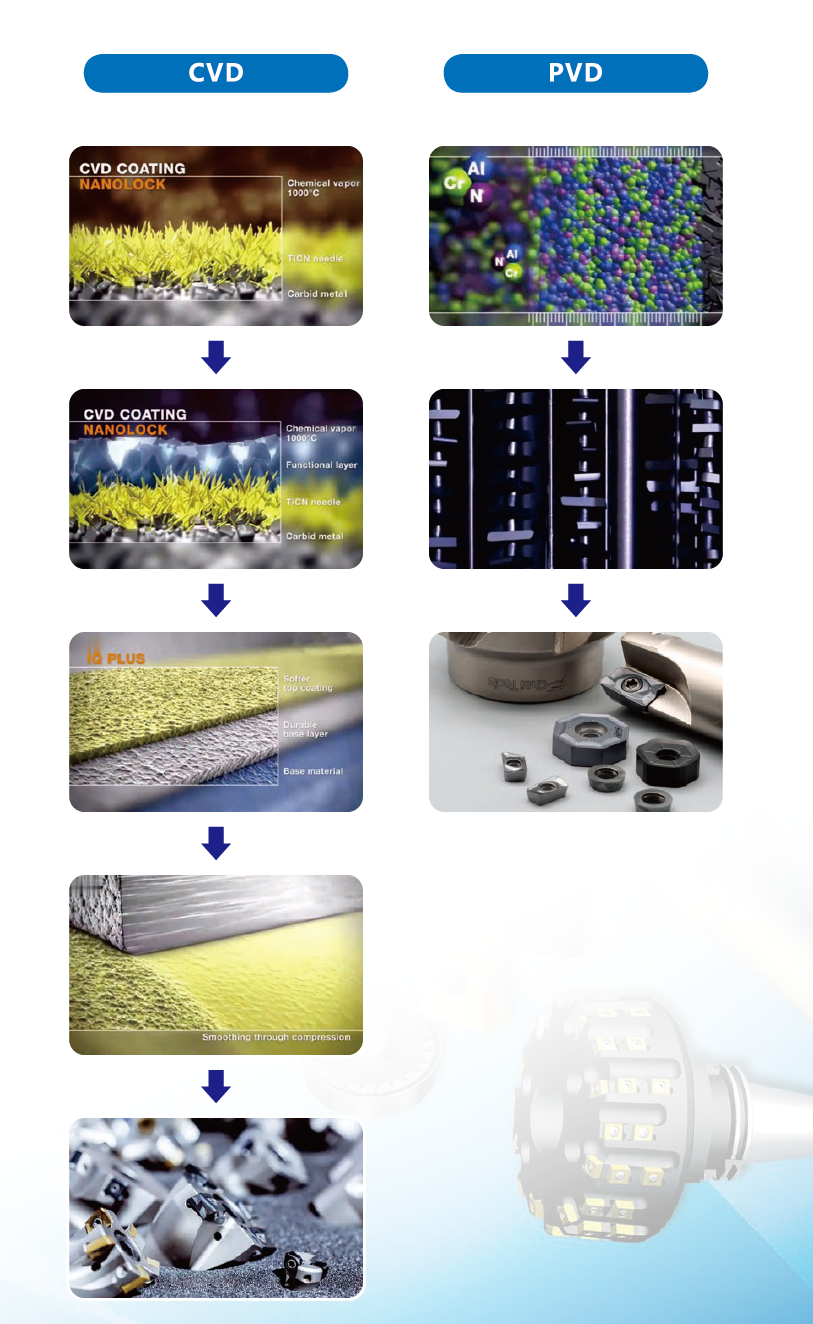

COATING DISPLAY

PACKAGE AND SHIPMENT

100% anti-water package.

One plastic pipe pack one piece,10 pcs per group.

Put goods enclosed with air bubble paper into box.

Other package is accepted according to customer's requirement.

Orders processed timely after the payment verification. we have many shipping ways, like DHL, Fedex, EMS and so on, will choose the best one for you.

Certificates

Production Equipment

QC Equipments

Advantages

1.Specialist in cemented carbide inserts for many years.

2. Factory price with 100% raw material quality

3. Free sample available for your testing.

4. Special size inserts can be customized.

FAQ

Q : Do you offer samples ? A : We will offer samples. But the customers need pay for the freight fee. Free sample depends on the quantity you buy.

Q : What payment can you accept ? TT.PayPal. L/C

Q: How long can the cemented carbide blade be used ? The service life of ordinary carbide turning tools is 60 minutes, and the specified service life is relatively short. This is because the tools are simple, the manufacturing cost is low, the grinding is convenient, and the service life of indexable carbide turning tools is 30-45 minutes. The specified service life is short, because the cutting edge is rapidly rotated, and the blade is easy to replace.

Q: How to select suitable inserts for different processing materials ? P Suitable for machining steel parts. M belongs to general cemented carbide, K is suitable for processing cast iron, and it is better not to process steel parts. The material used for rough machining is soft, impact resistant but short in life. Hard for finish machining, long service life.