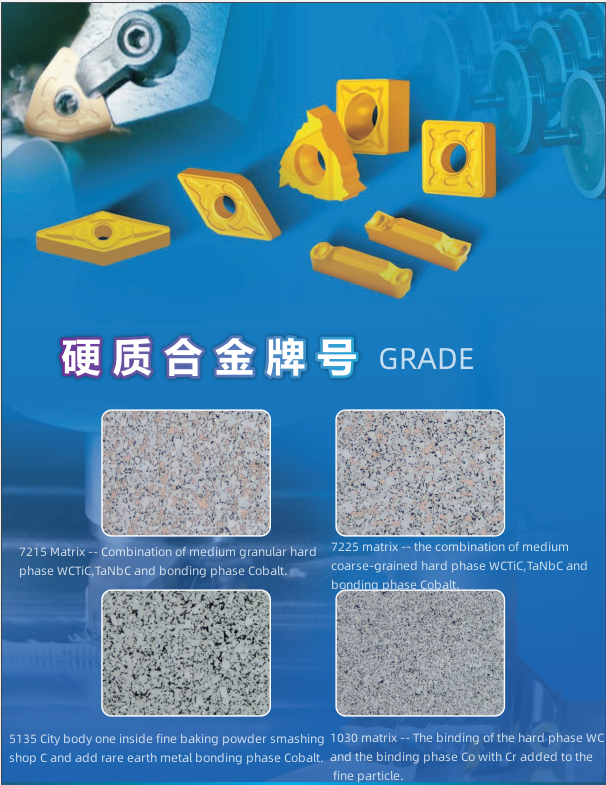

RPMT RDMW1204MO Indexable Milling Insert Carbide Inserts Lathe Tools Face Milling Cutter

Material Grade Introduction

Introduction of turning material introduction:

7215 has high strength and toughness of high toxicity resistance matrix, combined

with MT-TICN, AL2O3,TIN excellent combination of coating process, and then

through advanced coating post-treatment to eliminate the internal stress of blade layer, suitable for ordinary steel finishing.

7125 edge safety of high strength, high toughness matrix combined with MT-TICN and superfriction AL203 coating process, and then through advanced coating post-treatment process to eliminate the internal stress of the coating, suitable for ordinary steel rough processing, semi-finishing and part of the workpiece roughness requirements are not high finishing.

4025 high corrosion resistance, and through a certain pressure sintering process of high strength matrix and MT-TICN and super thick AL2O3 coating excellent combination, with advanced coating post-treatment technology to obtain smooth coating surface, suitable for the rough machining, semi-finishing and finishing of cast iron.

1030 fine grain, excellent deformation resistance and through the pressure sintering process to obtain ultra-high strength and wear resistance matrix, with nano PVD coating process, and then through advanced coating post-treatment to obtain smooth coating surface, suitable for ordinary steel finishing, quenched steel, chromium plated steel and stainless steel semi-finishing and finishing.

1120 ultra-fine grain, excellent deformation resistance, and through the pressure sintering process to obtain high strength and wear resistance matrix, with nano SI containing PVD coating process, after advanced coating post-treatment to obtain smooth coating surface. Suitable for grooving and cutting of ordinary steel, hardened steel and cast iron.

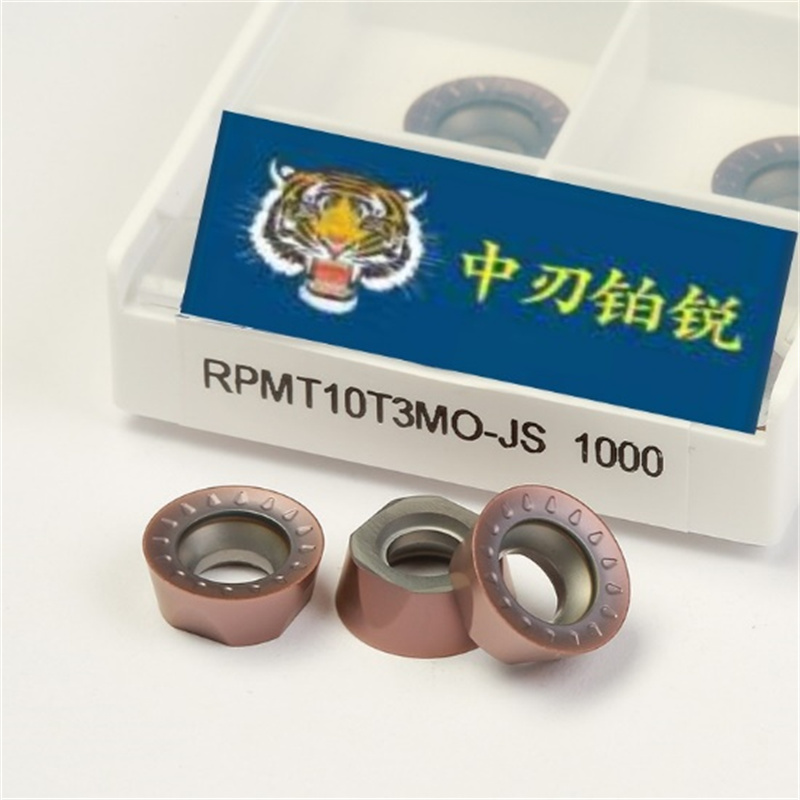

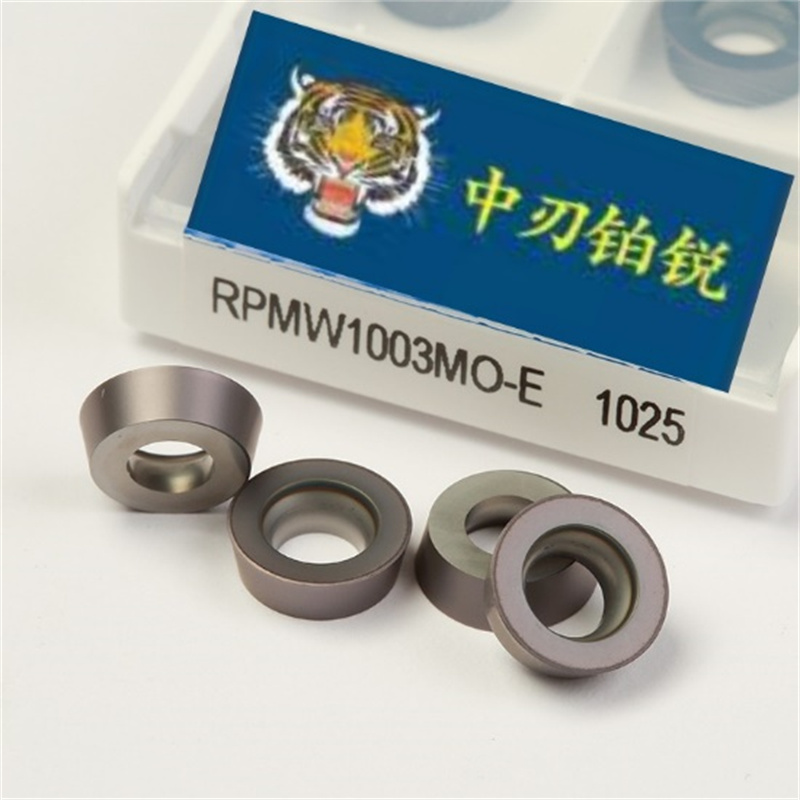

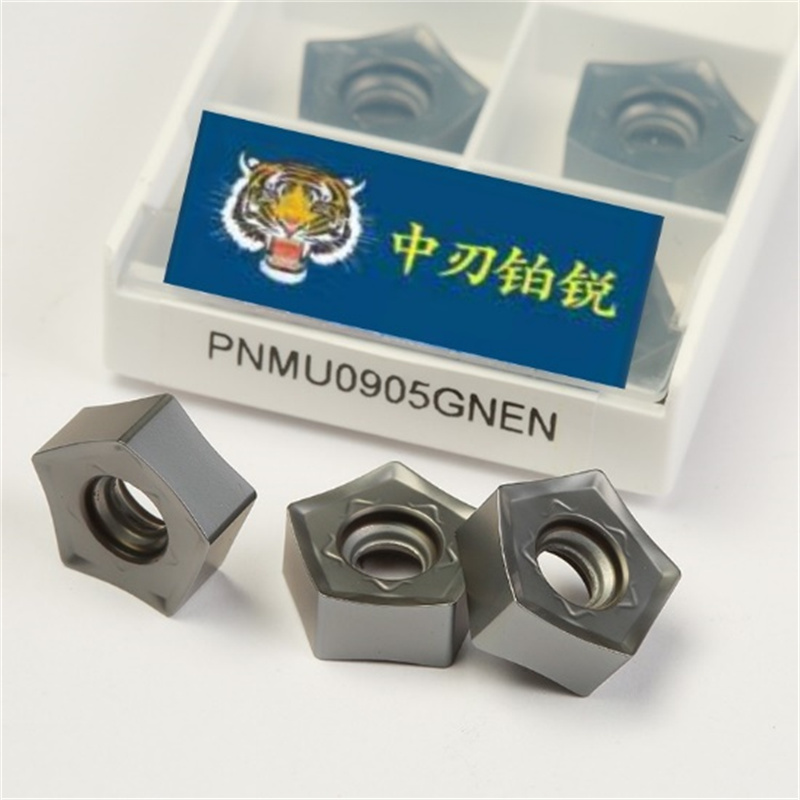

Introduction of milling and drilling materials

1030 NC-TIALN coating combined with strong and ductile matrix of fine particles is suitable for coarse and semi-finished milling of all kinds of processed materials. Grooving, cutting and drilling of half aperture.

1130 NC-TIALN coating containing SI is combined with fine particles and good toughness of hard alloy matrix, suitable for stainless steel, cast iron phase and semi-finish to processing, to achieve a perfect combination of safety and wear resistance.

5035 added wear and high temperature resistance elements of CVD coating, high coating hardness and excellent high temperature resistance to provide effective protection for the cutting edge, special coating treatment technology, coating and matrix more firmly, suitable for high temperature alloy, titanium alloy materials precision milling processing.

5135 NC-TIALN coating containing SI combined with carbide matrix with excellent impact toughness, suitable for steel parts, stainless steel, grooving, cutting deep cutting, fast feeding processing and large aperture drilling processing.

Application

Main Application: For processing carbon steel, cast iron, stainless steel

To the different hardness of mould workpieces,we can evaluare the life of cutting tools accurately. Profession at milling steel or stainless steel milling or iron cast milling or aluminum alloy ,our milling inserts are exceptionally made from quality ground ultra-fine carbide, and thinnest AlTiN high Al coating technology. These make Our milling cutter have ideal processing effect and stable quality to the highest.

Product Specifications

|

Type |

Dimension(mm) |

||

|

D |

S |

D1 |

|

|

RDMW120400-PR |

12.00 |

4.76 |

4.40 |

|

RDMW1204MOT-PM |

12.00 |

4.76 |

4.40 |

|

RDMW1204MO-TT |

12.00 |

4.76 |

4.40 |

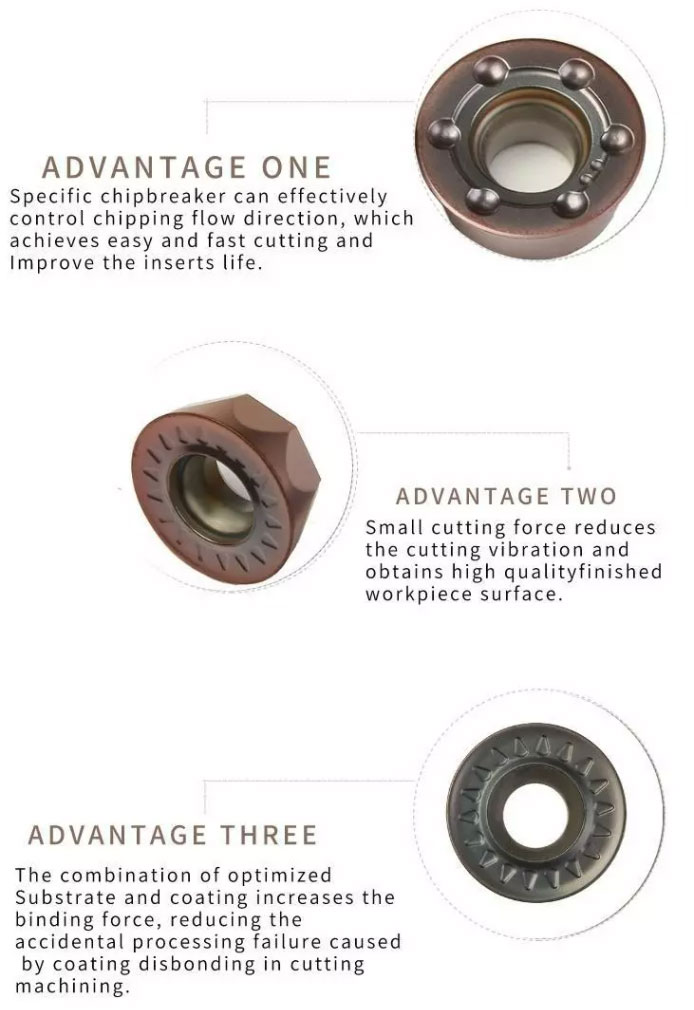

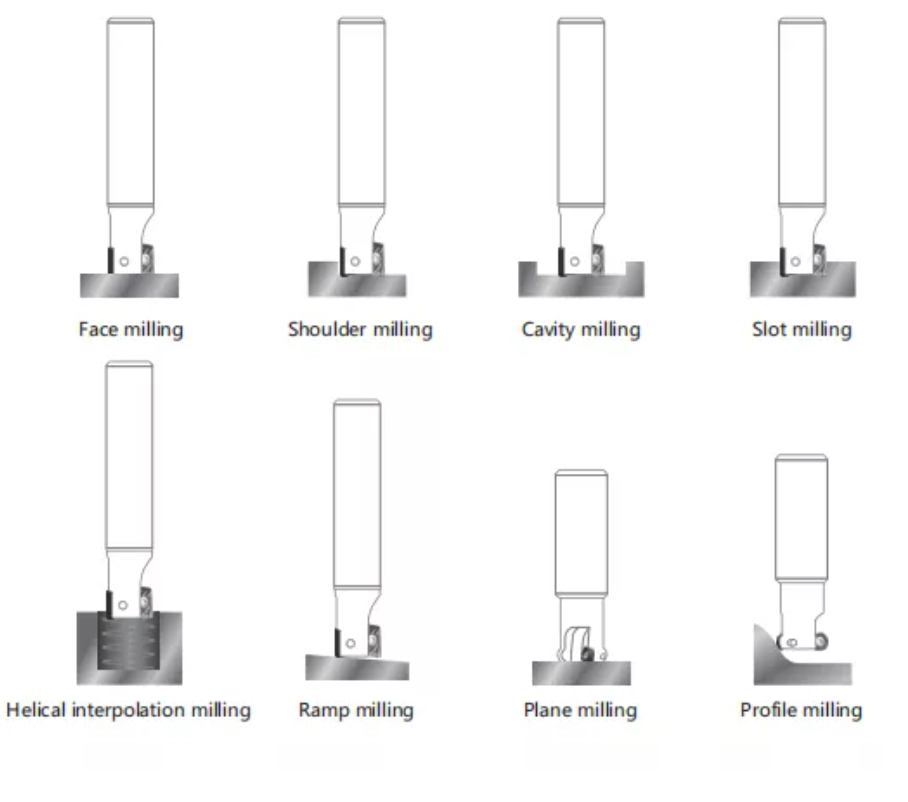

Whether you need a general milling or heavy milling inserts for face milling, shoulder milling, slot milling, profile milling, or ramp milling, or even milling higher requirements of surface smoothness, Our engineer can turn your design into a milling insert in just days.

Coating Display

Certificates

Production Equipment

QC Equipments

Our Service

Pre-sale Service:

We have professional sales staff, who can get to know the details about your needs and offer feedback.

Sales Service:

After the signing of the contract, our professional sales staff will communicate and work on the production schedules or your change of demand.

After-sale Service:

We will arrange the returning and changing of the products timely if they have quality problems. At the same time, return visits will be made regularly to know service condition of our products.