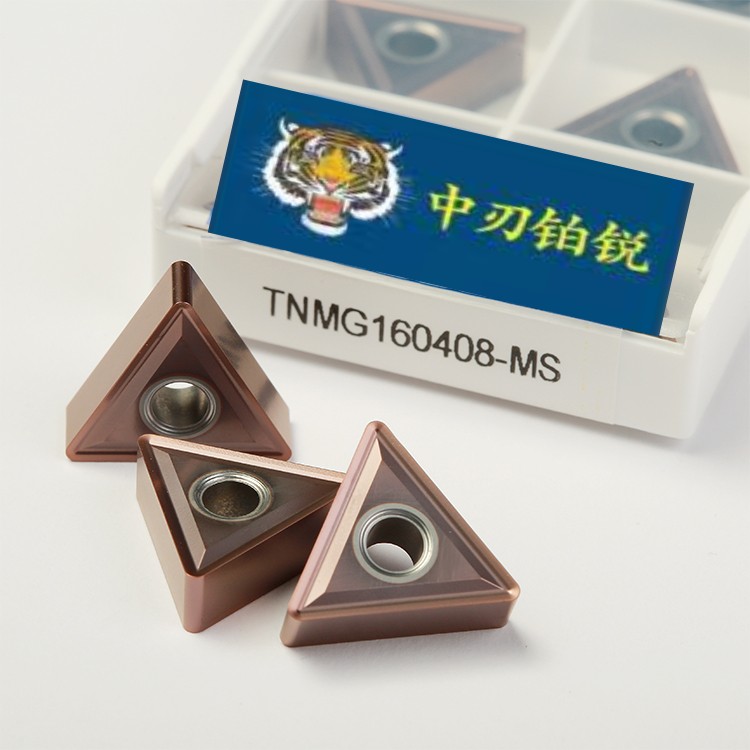

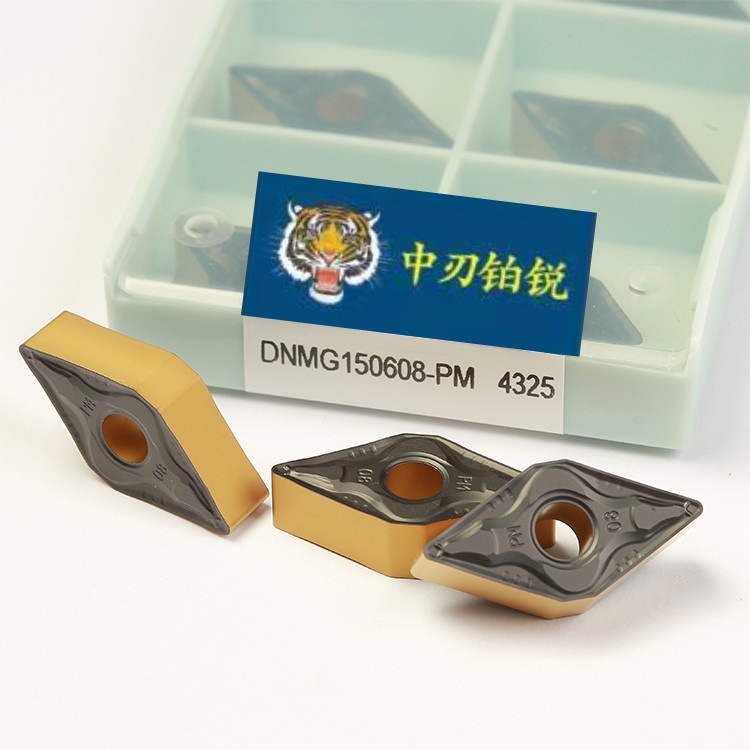

DNMG Insert and TNMG Insert

When making the choice of turning insert, going for the right insert of required job is just half the battle done. There are also steps like choosing the best chip breaker and grade that also need to be done. Whether you are going for a DNMG inserts or a TNMG inserts, the very first thing that you need to consider is whether you are simple going for general turning or for finishing or roughing. Here, it is important to note that the negative inserts tend to be the strongest. Thus, they are the most perfect options for general turning and roughing applications. That’s because they make way for deep cut depths and higher feed rates because of thickness and strong insert shapes.

For finishing jobs, the positive inserts always serve as the best option because they have the ability of creating less cutting forces. Therefore, they can easily get away with low cut depths while eliminating vibration at the same time. The DNMG or Diamond 55 degree insert is one of the most well-known roughing inserts. These inserts come with 55 degree included angle and can effectively be used for shaft turning and recessing. They are preferred over the TNMG inserts mainly because they produce less cutting force.

Post time: Jul-17-2024