Choosing the correct coating for a carbide insert is a critical decision that directly impacts machining performance, tool life, and overall productivity. With a variety of coating options available, it is essential to consider several factors to ensure the optimal selection for specific machining applications.

One of the primary considerations when choosing the correct coating for a carbide insert is the material being machined. Different coatings are designed to withstand the unique properties of various materials, such as aluminum, steel, stainless steel, or high-temperature alloys. For instance, machining abrasive materials like cast iron may require a coating with high wear resistance, while cutting aluminum may demand a coating that reduces built-up edge and chip adhesion.

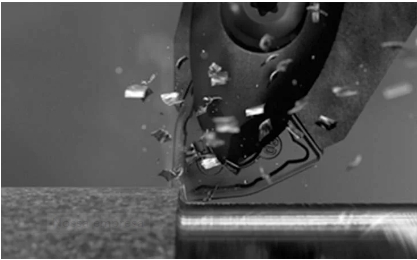

Another crucial factor to consider is the type of machining operation involved, whether it is turning, milling, drilling, or threading. Each operation imposes different demands on the cutting tool, and the coating must be selected to withstand the specific challenges associated with the process, such as heat generation, chip formation, and tool wear.

Furthermore, the cutting parameters, including cutting speed, feed rate, and depth of cut, play a significant role in determining the most suitable coating for a carbide insert. Higher cutting speeds and feeds may necessitate coatings with improved heat resistance and lubricity to withstand the increased thermal and mechanical loads.

Post time: May-11-2024