PCD cutter heads for non-ferrous materials, cermet, uncoated and PVD-coated carbide materials.

Sandvik blades and materials for milling non-ferrous materials

The non-ferrous metal blade material series includes PCD insert welding material, cermet material, PVD coated carbide material and uncoated carbide material for various processing conditions. Use the information below to find suitable materials for production.

H13A

Hard uncoated material for roughing to semi-finishing with sharp cutting edges under normal to stable conditions. Excellent surface quality is ensured in both wet and dry machining.

H10

Very hard uncoated material for light load roughing to finishing with sharp cutting edges under stable conditions for wet and dry machining with high surface quality requirements.

CD10

Polycrystalline diamond insert welding material (PCD) with sharp cutting edge for light load roughing to finishing under stable conditions in wet and dry machining where surface quality and machining stability are required. Ideal for abrasive materials.

Supplementary material

CT530

Medium hard uncoated cermet material for finishing at increased cutting speeds under stable conditions in wet and dry machining.

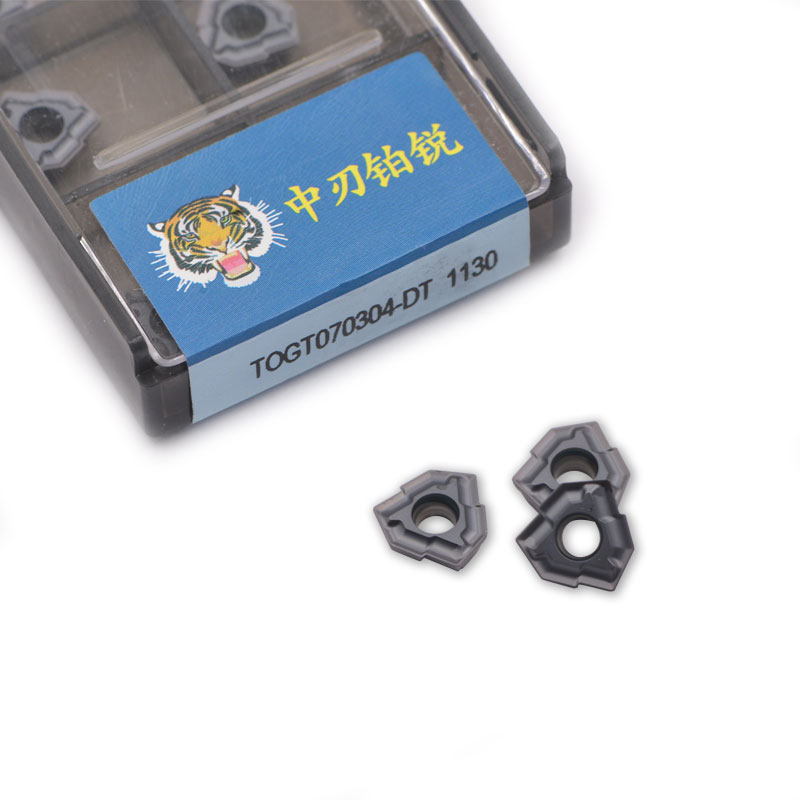

GC1130

The hard thin PVD coating material with Zertivo 64 technology is used for rough to semi-finishing under normal working conditions for wet and dry machining with low surface quality requirements.

H10F

Hard uncoated material for light load roughing to finishing with sharp cutting edges under normal conditions for wet and dry machining where good surface quality is required.

GC1030

Hard, thin PVD coating material for rough to semi-finishing under normal working conditions for wet and dry machining with low surface quality requirements

Post time: Aug-27-2024