High quality APMT CNC inserts type for milling APMT1604PDER-HT 1120 Direct supply from manufacturer

Basic Information

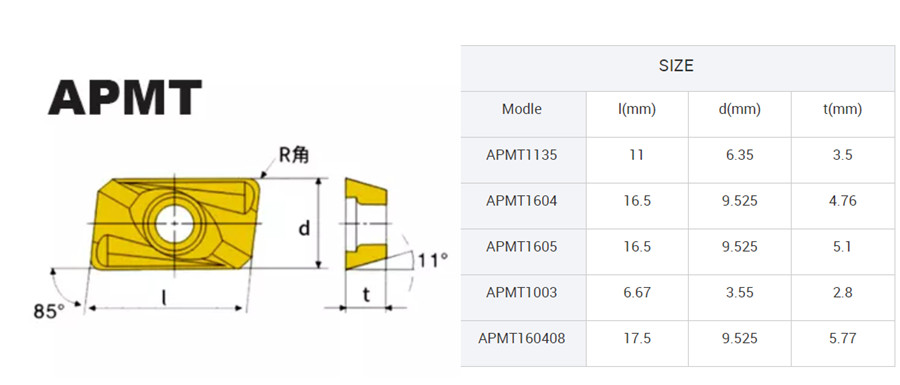

Carbide APMT PVD Coated inserts are commonly used for indexable square shoulder end milling cutters and face milling cutters. The APMT inserts are with precision-molded I.C., positive molded chip breaker. They have a sharp and honed cutting edge and 11° relief angle. They are with screw holes created in compliance with ISO. Typically, it is viewed as with 2 cutting edges. However, they actually have 4 cutting edges. when they are installed on 90° indexable milling cutters and both edges become dull, they can be installed on 75° indexable milling cutters  and continue other milling applications with the other two edges.APMT will be a great choice for end users, since it can significantly improve productivity.

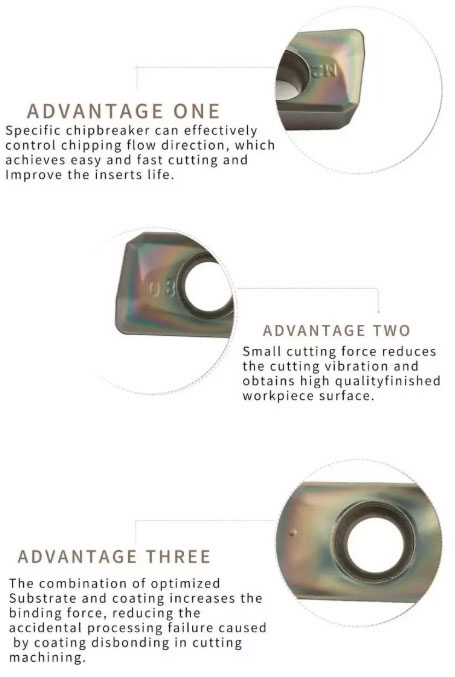

Advantages

1. Good wear resistance, high bending strength,strong bonding resistance, excellent heat resistance,impact toughness and high hardness.

2. Long service life and easy to assembly, no crack or chipping

3. Specification and accuracy of our CNC inserts type is fully compliance with ISO standard.

Features

1. High surface quality

2. Excellent impact toughness and wear resistance

3. Good universality

4. Strict quality management system to guarantee the consistent quality

5. Excellent wear resistance, good hot hardness, improve Production efficience.

6. Precision ground and polished, perfect cutting effect

7. PVD coating ensure the longer tool life.

Application

Main Application: For processing carbon steel, cast iron, stainless steel

Industry of application: CNC turning and milling tungsten carbide tools products inserts are widely used in: Automotive manufacturing industry, Mold manufacturing industry, Aviation industry, Defense industry, Heavy processing industry and many other field.

we can produce various types tungsten carbide cutting tools insert according to different customized drawings.

we can provide the overall supporting solutions for the machining field.

Product Specifications

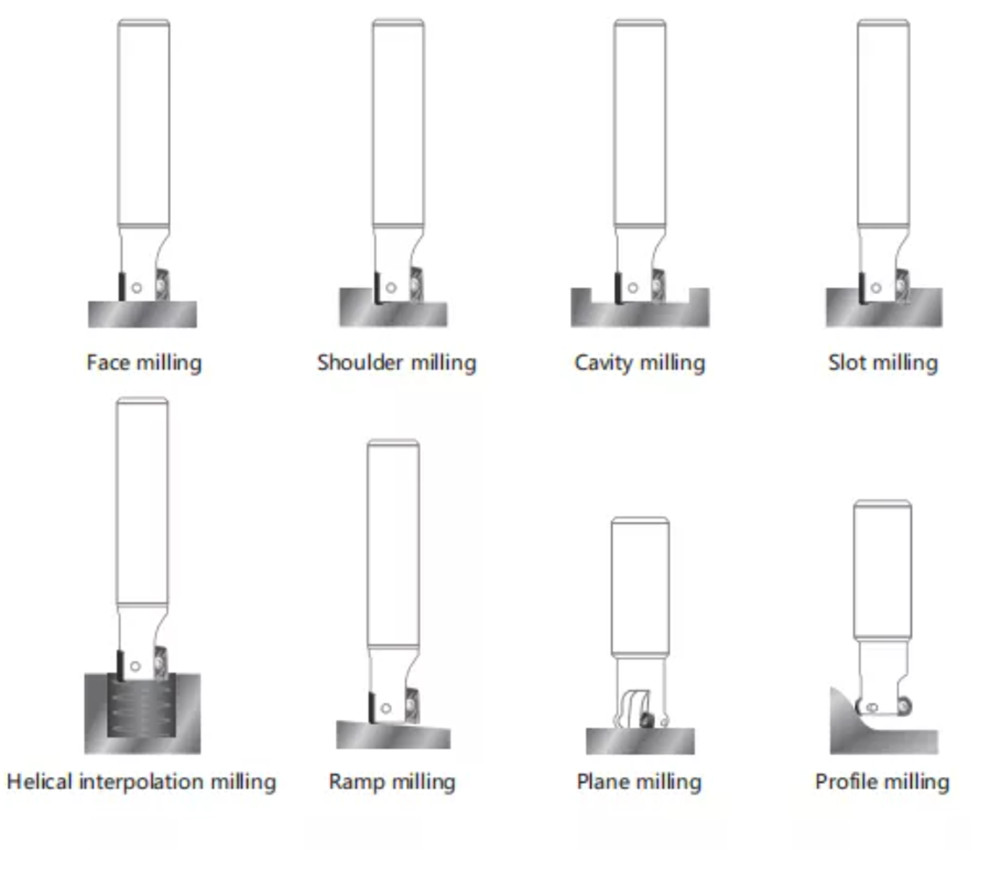

Whether you need a general milling or heavy milling inserts for face milling, shoulder milling, slot milling, profile milling, or ramp milling, or even milling higher requirements of surface smoothness, Our engineer can turn your design into a milling insert in just days.

Coating Display

Certificates

Production Equipment

QC Equipments